Introduction

FK Engineering proudly announces the successful completion of the Entree Food project — a state-of-the-art commercial food production and service facility. This project involved a comprehensive scope of work, including civil, mechanical, and electrical installations, as well as the integration of advanced food processing and kitchen systems.

Entree Food is known for its commitment to quality, safety, and innovation in the food industry. With this project, FK Engineering ensured that every aspect of the facility meets international standards, optimizes workflow, and supports large-scale operations.

Project Overview

The Entree Food project was designed to transform an existing building into a fully functional, high-capacity food production and service hub. The facility needed to accommodate:

- Bulk food preparation

- Cold and dry storage

- Modern cooking and packaging systems

- Staff workstations and quality control areas

FK Engineering’s scope included:

- Complete civil works for structural readiness.

- Mechanical installation of industrial food equipment.

- Electrical infrastructure for heavy-duty operations.

- Testing and commissioning to ensure smooth operations.

FK Engineering began with extensive civil work to prepare the site. This phase ensured that the structure could support heavy industrial machinery and comply with hygiene and safety codes.

Key civil work tasks included:

- Flooring Reinforcement: Installing heavy-duty, non-slip, easy-to-clean industrial flooring suitable for wet and dry food production areas.

- Wall and Ceiling Finishes: Using food-grade, washable panels to maintain hygiene and prevent contamination.

- Drainage Systems: Designing and installing a network of floor drains to ensure quick water removal and maintain a dry, safe work environment.

- Partition Construction: Creating separate zones for raw material handling, cooking, packaging, and storage to ensure a smooth production flow and meet food safety regulations.

Once the civil foundation was ready, FK Engineering moved into mechanical installations. This phase brought the facility to life by integrating the necessary production and storage equipment.

Major mechanical works included:

- Installation of Commercial Cooking Equipment: Industrial ovens, steam kettles, grills, and fryers — all strategically placed for workflow efficiency.

- Cold Storage Units: Large walk-in refrigerators and freezers for perishable goods, fitted with energy-efficient insulation and temperature control systems.

- Food Processing Machines: Mixers, slicers, grinders, and packaging units, each positioned according to the production layout plan.

- Ventilation and Exhaust Systems: A complete hood and duct system to remove heat, smoke, and odors while ensuring fresh air circulation in the workspace.

- Material Handling Systems: Stainless steel work tables, racks, and conveyors for easy transfer of ingredients and finished products.

Electrical Setup

With the machinery in place, FK Engineering executed a robust electrical plan to power the facility safely and efficiently.

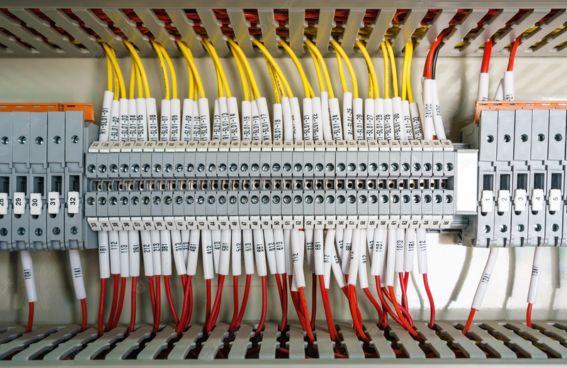

- Main Power Distribution: Installation of high-capacity distribution boards to handle heavy electrical loads from industrial equipment.

- Dedicated Circuitry: Separate circuits for cooking appliances, refrigeration units, and processing machines to prevent overloads.

- Energy Efficiency Systems: LED lighting for all work areas, motion sensors in storage spaces, and timed power cut-off systems for non-operational hours.

- Backup Power Integration: A generator and UPS system to ensure uninterrupted production in case of power outages.

- Control Panels and Automation: Centralized panels for monitoring equipment performance, temperature controls, and safety alarms.

Final Finishing and Testing

After the main installations, FK Engineering conducted a rigorous finishing phase to ensure every system was operational and met Entree Food’s standards.

This phase included:

- Equipment Calibration: Adjusting machinery for optimal performance and accuracy in food processing.

- Water Supply & Sanitation Checks: Ensuring consistent hot and cold water availability and proper waste disposal.

- Safety Inspections: Testing fire suppression systems, emergency exits, and ventilation for compliance.

- Staff Training: Providing EntreeFood’s team with operational training for equipment handling, maintenance, and safety protocols.

Challenges & Solutions

Every large-scale project faces challenges. For Entree Food, the biggest hurdles were:

- Tight Deadlines: The facility needed to be operational before a major product launch.

Solution: FK Engineering organized parallel work teams for civil, mechanical, and electrical tasks to save time. - Space Optimization: Balancing heavy machinery placement with safe staff movement.

Solution: A detailed 3D layout was created before installation to ensure maximum efficiency. - Hygiene Compliance: Meeting strict food industry hygiene regulations.

Solution: Use of only food-grade materials for all contact surfaces and seamless wall-floor joints to avoid dirt accumulation.

Project Outcomes

Upon completion, Entree Food now benefits from:

- Higher Production Capacity: Increased output by 40% compared to their previous setup.

- Energy Efficiency: Power consumption reduced by 20% due to modern systems.

- Enhanced Hygiene: The facility exceeds food safety standards, reducing the risk of contamination.

- Staff Efficiency: Improved workflow reduces preparation time and increases productivity.

Conclusion

The Entree Food project showcases FK Engineering’s ability to deliver turnkey industrial solutions that meet the highest standards of quality, safety, and efficiency. By handling civil, mechanical, and electrical phases with precision, FK Engineering has created a facility that will support Entree Food’s growth for years to come.

Entree Food’s management praised FK Engineering for their dedication, technical expertise, and timely completion of the project — a partnership built on trust and excellence.