Installation and Commissioning

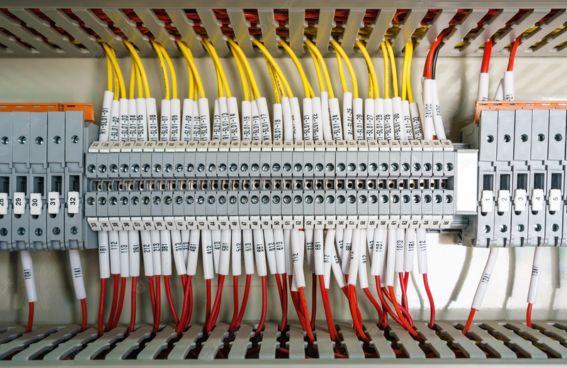

HT / LT Panels

Installation and commissioning

he process for installing, testing, and commissioning electrical components like low voltage (LV) panels, distribution boards, power factor improvement plants, and Motor Control Centers (MCCs) involves meticulous steps to ensure safety, compliance, and optimal performance.

Installation and commissioning of synchronizing and generator panels involve a site survey, panel mounting, precise wiring to generators and loads, and comprehensive testing to ensure voltage, frequency, and phase matching.

Installing and commissioning an ATS/AMF panel involves meticulous physical and electrical inspections, correct control wiring, and comprehensive testing of the panel's automatic transfer of load between the main power source and a standby generator

Installation and commissioning of HT panels involve physically mounting and securing the panels, connecting busbars and cables, and conducting extensive testing to ensure safety, reliability, and compliance with standards before energization.

Cable laying involves carefully pulling and routing the cable along a designated path using specialized equipment to prevent damage, while termination involves preparing the cable ends to make secure, reliable connections to electrical equipment or other cables.

Testing and commissioning a transformer involves a rigorous process to verify its performance and identify potential issues before and after installation.

Motor testing and maintenance involve regular visual and mechanical checks for wear, leaks, and dirt, alongside electrical tests of windings, connections, and voltage.

Generator installation involves site preparation, foundation laying, and careful electrical/fuel connections, while commissioning verifies operational readiness. Maintenance includes regular visual inspections, fluid level checks, load testing, and filter changes to ensure reliability, maximize performance, and extend the generator's lifespan. Safety, proper ventilation, grounding, and compliance with regulations are critical throughout all stages.

Electrifying an office building involves designing an integrated electrical system, installing appropriate wiring and cables for lighting and power, and laying power cables for distribution and connections.

Installing fire alarm and external lighting systems involves professional planning and installation to ensure safety and code compliance. For fire alarms, this includes installing a control panel, smoke detectors, pull stations, and notification devices, running wires, and testing the entire system.

To install a light fixture, first turn off the power at the circuit breaker, then remove the old fixture if there is one. Install the new mounting bracket and carefully connect the wires, matching colors (black to black, white to white) and connecting the earth wire to the fixture's earth terminal.

To install a cable tray system, plan the route and gather materials, then mount support brackets at the correct spacing. Assemble and position the tray sections onto the supports, securing them with appropriate hardware. Install bends, risers, and fittings as needed for changes in direction. Finally, lay and organize cables within the completed tray, securing them with ties, and ensure the system is properly grounded and bonded for safety.

To complete a substation erection according to K-Electric (KE)/ WAPDA standards, the process involves meticulously installing LT poles and associated earthing, followed by stringing of overhead conductors and the laying of both high-tension (HT) and low-tension (LT) cables. This installation must adhere to pre-approved shop drawings and technical specifications, which detail exact routes, connections, and materials, including all nuts, bolts, and tags needed for a complete and functional system, with final commissioning and testing as the last steps.

Data communication networking solutions involve the technologies, hardware, and software that enable devices to exchange data reliably and securely over a network.

To implement a complete electrical energy system analyzer, you need to install monitoring devices like current transformers and data loggers, connect them to a software platform for real-time monitoring and analysis, and set up reporting features to track energy usage, identify inefficiencies, and benchmark performance against targets. Regular maintenance, integration with Building Management Systems (BMS), and expert data interpretation are crucial for accurate results and maximizing energy savings.

Energy management solutions are systems and strategies designed to monitor, analyze, and control energy consumption to improve efficiency, reduce costs, and lower carbon emissions.

Feature text for the installation of PLC-controlled panels emphasizes rugged construction, ease of integration, high reliability, and safety features like proper grounding and interlocks to ensure robust, fault-tolerant automation for industrial processes

VFD installation involves physically mounting the drive in a clean, dry, ventilated location, and wiring it to the motor and power supply while ensuring proper grounding and correct circuit breaker ratings.

Pre detective measurements" is not a standard maintenance term; it likely refers to predictive maintenance or condition-based maintenance, where measurements are taken to predict future failures or assess current conditions to determine when maintenance is needed. These methods use data and inspections to anticipate maintenance, unlike purely reactive or scheduled preventive approaches, allowing for more efficient resource allocation and reduced downtime.

A Building Management System (BMS), also called a Building Automation System (BAS), is a computer-based, centralized control system for a building's technical installations like HVAC, lighting, security, and fire systems.

Bus risers are installations of busway (a system of conductors within an enclosure) in a vertical orientation.

To install a factory temperature control system, you must mount the sensor and actuator, then wire them to the temperature controller.