Testing and Diagnosis

Testing and Diagnosis

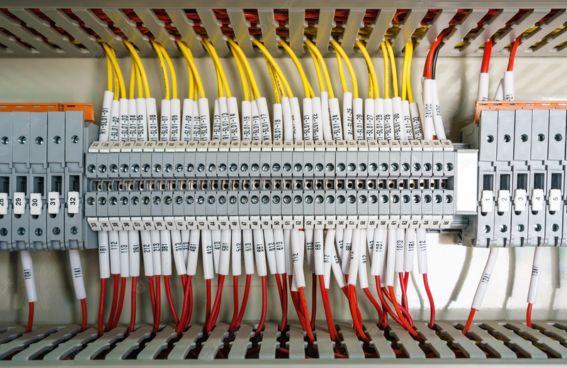

Inspecting electrical system components involves a visual assessment and testing of all parts of the electrical system to ensure safety and compliance with standards.

True RMS (Root Mean Square) testing provides an accurate measurement of the effective voltage or current in an AC (alternating current) circuit, especially for non-sinusoidal and distorted waveforms.

Instantaneous harmonics distortion testing involves analyzing harmonic components of a signal in real-time to assess distortion, often in power systems or audio equipment.

Power factor testing is a diagnostic method for evaluating the condition of insulation in high-voltage electrical equipment like transformers and cables by measuring the dielectric losses.

Voltage drop across a contact is the reduction in electrical potential that occurs due to the contact's resistance, often caused by dirt, corrosion, or loose connections.

Phase balance testing verifies that a three-phase system maintains consistent voltage and current across all phases, ensuring proper equipment operation and preventing damage due to imbalances.

Energy analysis services and reports provide insights into energy consumption, market trends, and efficiency improvements for various sectors, utilizing data analysis, energy auditing, and performance monitoring

CABLES (LV, MV & HV)

Pre-Installation Tests

Visual inspection is the fundamental process of observing a product, component, or asset with the human eye to detect defects, flaws, or abnormalities, ensuring quality and proper functioning

An Insulation Resistance Test (IR Test) evaluates an electrical system's insulation by applying a high DC voltage to measure the leakage current and calculate insulation resistance using a megohmmeter.

A continuity test is a method to check if an electrical circuit has a complete, uninterrupted path for current to flow. Performed using a multimeter set to its continuity (beeper) mode, the test involves touching the multimeter probes to two points in a circuit

A Conductor Resistance Test measures the DC resistance of a conductor or cable to verify its quality and integrity, ensuring it's within acceptable standards.

Post-Installation / Commissioning Tests

A high potential (Hipot) test, or dielectric withstand test, is a safety and quality test that applies a high AC or DC voltage to electrical equipment to verify the integrity and strength of its insulation, ensuring it can safely handle overvoltage conditions and prevent current leakage.

A Very Low Frequency (VLF) test assesses the insulation integrity of medium- and high-voltage cables, rotating machinery, and other electrical equipment by applying an alternating voltage at a very low frequency (0.01 Hz to 0.1 Hz) to detect insulation weaknesses like cracks or voids.

A partial discharge (PD) test assesses the insulation health of electrical assets by detecting small, localized electrical discharges that don't completely bridge the gap between conductors.

A sheath integrity test applies a high DC voltage between the cable's screen and earth to confirm the outer sheath is intact and undamaged, preventing moisture ingress and electrical faults.

The Tan Delta (Dissipation Factor) Test is a diagnostic method to assess the health and quality of electrical insulation in equipment like transformers, cables, and rotating machines.

TRANSFORMERS (Power & Distribution)

Factory Tests (Type & Routine)

The Transformer Turns Ratio (TTR) test determines the ratio of turns (or voltages) between the high-voltage (HV) and low-voltage (LV) windings of a transformer,

A winding resistance test assesses the continuity, condition, and integrity of electrical windings in equipment like motors and transformers.

Vector group verification for a transformer involves conducting a vector group test to confirm the phase relationship between its primary and secondary windings, ensuring it aligns with the nameplate's vector group designation

A polarity test is an essential safety check in electrical systems and transformers to verify that conductors are connected to the correct terminals,

The Magnetization Current Test, also known as the Excitation Current Test or No-Load Current Test, is an electrical test performed on transformers to assess the integrity of their magnetic core, windings, and tap changers.

An Insulation Resistance (IR) test uses a megohmmeter to apply a high DC voltage to an electrical system, measuring the resulting leakage current to determine the insulation resistance.

The Power Factor / Tan Delta test is a diagnostic test used to evaluate the dielectric insulation of high-voltage equipment, such as transformers, cables, and motors.

Impedance voltage measurement involves applying an AC voltage to a device and measuring the resulting current, then calculating impedance (Z) as the ratio of the voltage to the current, often expressed in ohms.

Load and no-load losses in a transformer are measured through distinct tests: the Open-Circuit Test (No-Load Test) for no-load losses (iron losses) and the Short-Circuit Test for load losses (copper losses).

A temperature rise test is a type test for electrical equipment that measures the increase in component temperatures under rated current to ensure the equipment doesn't overheat

An Induced Overvoltage Test, also known as a double-frequency or overpotential test, verifies a transformer's interturn and longitudinal insulation by applying a higher-than-normal frequency (typically double the rated frequency) to the low-voltage winding to induce high voltage in the high-voltage winding

An Applied Voltage Test, or AC HiPot test, is a safety test that applies an alternating current (AC) high voltage significantly above normal operating levels to an electrical device to verify the integrity of its insulation.

Sweep Frequency Response Analysis (SFRA) is an offline diagnostic test that evaluates the mechanical integrity of power transformers by measuring their electrical transfer functions over a wide frequency range.

Oil quality tests include visual inspection for color, clarity, and smell, but more precise scientific tests measure viscosity, particle count, moisture content (Karl Fischer or crackle test)

MEDIUM VOLTAGE SWITCHGEAR (11 kV – 33kV)

Routine Electrical Tests

An Insulation Resistance (IR) test uses a megohmmeter to apply a high DC voltage to an electrical system, measuring the resulting leakage current to determine the insulation resistance.

An Insulation Resistance (IR) test uses a megohmmeter to apply a high DC voltage to an electrical system, measuring the resulting leakage current to determine the insulation resistance.

A high potential (Hipot) test, or dielectric withstand test, is a safety and quality test that applies a high AC or DC voltage to electrical equipment to verify the integrity and strength of its insulation, ensuring it can safely handle overvoltage conditions and prevent current leakage.

A contact resistance test, also known as a Ductor test, measures the resistance of electrical connections at the micro- or milli-ohm level using Ohm's Law to detect issues like loose connections, oxidation, or high resistance that can lead to system failures or dangerous hot spots.

A primary injection test is an electrical test that applies high current directly to the primary side of a circuit breaker or protective device to verify the entire protection chain, including current transformers, wiring, and the trip unit itself, will function correctly under simulated fault conditions.

A secondary injection test is an electrical system diagnostic used to verify the functionality of protection relays and their associated circuits, such as those in transformers and switchgear.

Functional testing in software development verifies that an application's features work as specified by the functional requirements, focusing on the "what" the system does rather than the "how well".

A good reaction time depends on the task, with averages for the general population around 250 milliseconds (ms) for visual stimuli and faster for auditory or touch stimuli.

A partial discharge (PD) test is a non-destructive diagnostic technique used to evaluate the health of electrical insulation in high-voltage equipment like transformers, motors, and cables.

A vacuum integrity test confirms that the vacuum inside an object, typically a vacuum interrupter in an electrical circuit breaker, is sufficient for its intended function.

MEDIUM VOLTAGE SWITCHGEAR (11 kV – 33kV)

Routine Electrical Tests

A visual inspection is an inspection of an asset made using only the naked eye

An Insulation Resistance (IR) test uses a megohmmeter to apply a high DC voltage to an electrical system, measuring the resulting leakage current to determine the insulation resistance.

A high potential (hipot) test, or dielectric withstand test, is a safety and quality test that applies an overvoltage to the insulation of an electrical device or system to ensure its dielectric strength is sufficient to prevent breakdown and ensure safe operation.

A contact resistance test, also known as a Ductor test, measures the resistance of electrical connections at the micro- or milli-ohm level using Ohm's Law to detect issues like loose connections, oxidation, or high resistance that can lead to system failures or dangerous hot spots.

A primary injection test is an electrical test that applies high current directly to the primary side of a circuit breaker or protective device to verify the entire protection chain, including current transformers, wiring, and the trip unit itself, will function correctly under simulated fault conditions.

A secondary injection test is an electrical system diagnostic used to verify the functionality of protection relays and their associated circuits, such as those in transformers and switchgear.

Functional testing is a software testing method that verifies if a system's features work correctly and meet their specified business requirements by comparing actual outputs with expected outputs for given inputs.

A good reaction time depends on the task, with averages for the general population around 250 milliseconds (ms) for visual stimuli and faster for auditory or touch stimuli.

A partial discharge (PD) test is a non-destructive diagnostic technique used to evaluate the health of electrical insulation in high-voltage equipment like transformers, motors, and cables.

A vacuum integrity test confirms that the vacuum inside an object, typically a vacuum interrupter in an electrical circuit breaker, is sufficient for its intended function.

MOTORS (Induction / Synchronous)

Routine Electrical Tests

An Insulation Resistance (IR) test uses a megohmmeter to apply a high DC voltage to an electrical system, measuring the resulting leakage current to determine the insulation resistance.

A winding resistance test assesses the continuity, condition, and integrity of electrical windings in equipment like motors and transformers.

A Polarization Index (PI) test is an insulation resistance test used on high-voltage motors and rotating machinery to assess the health of their winding insulation by measuring the resistance at one minute and then again at ten minutes after applying a high voltage.

A method of measuring current and speed by applying a voltage without attaching a load to the shaft, in order to determine various parameters from the data, or check the cause of malfunctions.

A Locked Rotor Test (or blocked rotor test) is performed on an electric motor, particularly induction motors, to determine its starting current and starting torque by physically preventing the rotor from rotating and applying a reduced voltage and frequency to the stator.

During vibration testing, engineers measure the specimen's response, such as acceleration or displacement, while applying harmonic excitation across a range of frequencies.

A "Current Balance Test" is ambiguous, but generally refers to either a human balance test to assess stability, like the Romberg Test or the 4-Stage Balance Test, or a transformer magnetic core balance test which checks for even magnetic flux in a transformer's core and windings by measuring voltages to ensure the core is stable and fault-free.

A surge test for an electric motor applies high-voltage pulses to its windings to identify insulation weaknesses, turn-to-turn shorts, and other defects by comparing the resulting voltage waveforms against a reference

Tan Delta and Partial Discharge (PD) testing are diagnostic methods to assess the health of insulation in high-voltage equipment, but they provide different information.

GROUNDING SYSTEM

Routine Electrical Tests

Earth resistance is measured using an Earth Resistance Tester, often employing the three-terminal method or fall of potential method.

A Soil Resistivity Test measures how well the ground conducts electricity, crucial for designing grounding systems for electrical infrastructure and assessing soil corrosivity.

An earth continuity test checks the integrity and low-resistance path of a protective earth conductor within an electrical system to ensure it can safely direct fault current to the ground.

PROTECTIVE RELAYS

Routine Electrical Tests

Secondary injection testing verifies the logic and wiring of a protection system, like a circuit breaker trip unit, by injecting low-level simulated fault currents or voltages into its secondary circuits rather than directly through its main power path.

A functional check is an additional check point that is required to calibrate an instrument. The options for a functional check are either pass or fail. For example, a functional check can record a temperature setting that contributes to either a pass or fail.

Relay coordination verification confirms that protective relays are correctly set to isolate a fault selectively and swiftly, ensuring only the closest device operates and leaving the rest of the system unaffected.

Communication skills assessment is a test to measure candidates' communication skills. It comprises verbal ability assessment, listening skills assessment, writing skills assessment and reading skills assessment.