Client: Bake Parlor Industries

Industry Type: Food Processing, Dairy / Bakers Products, or Packaging

Location: Karachi

Project Duration: 1-2 years

Scope: Complete turnkey industrial setup – Civil, Mechanical, Electrical, and Utilities Installation

1. Project Overview

Bake Parlor Industries is a forward-thinking company focused on delivering high-quality dairy-based food products to the market. When they decided to establish a modern, fully equipped production facility, they needed an engineering partner who could deliver excellence from start to finish.

They chose FK Engineering — and from the very first day, our team took full ownership of the project. From groundbreaking civil works to precision machinery installation and final commissioning, we transformed an empty plot into a fully functional, state-of-the-art industrial unit.

2. Civil Works – Building the Strong Foundation

A successful industrial project starts with solid civil engineering. At Bake Parlor, FK Engineering’s civil team ensured the facility’s infrastructure was not only robust but also designed for smooth operational flow.

Key Civil Works Completed:

- Site Preparation: Clearing, leveling, and compacting the land to meet structural load requirements.

- Foundation Construction: Deep RCC foundations capable of supporting heavy machinery and industrial loads.

- Structural Framing: Steel and RCC frame structure designed to provide maximum durability with minimal maintenance.

- Flooring: High-strength industrial concrete floors with epoxy coating for hygiene and ease of cleaning.

- Drainage System: Strategically designed drains to maintain a hygienic and dry work environment, essential for food/production industries.

- Office & Utility Spaces: Fully finished administrative block, control rooms, and staff amenities.

3. Mechanical Works – Installing the Heart of Production

Once the structure was ready, our mechanical engineering team moved in to install Bake Parlor’s core production systems.

We handled machinery procurement, transportation, installation, and alignment with utmost precision.

Key Mechanical Installations:

- Main Production Line Machinery: Fully automated dairy processing / food packaging line sourced from reputable international suppliers.

- Material Handling Systems: Conveyor belts, loaders, and feeders for smooth raw material movement.

- Storage Tanks & Silos: Food-grade stainless steel tanks with mixing and cooling features.

- Packaging Units: High-speed packaging machinery ensuring product freshness and shelf life.

- Piping & Utility Connections: Stainless steel process piping, water supply, and waste management systems.

Every machine was positioned with careful alignment to ensure efficiency, ease of maintenance, and compliance with safety standards.

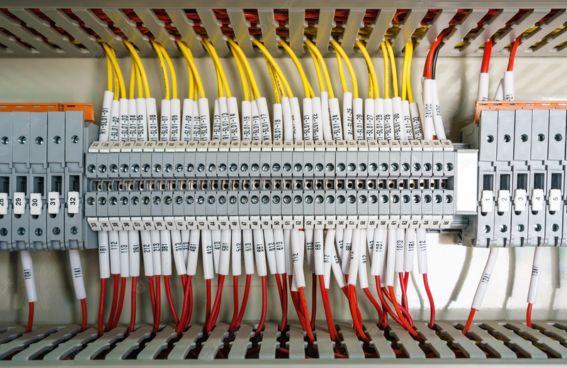

4. Electrical Works – Powering the Entire Facility

An industrial plant’s productivity depends heavily on a stable and safe electrical system. At Bake Parlor, FK Engineering’s electrical team delivered a cutting-edge power distribution setup to support continuous operations.

Electrical Setup Highlights:

- Main Power Panels & Sub-Distribution Boards: Designed to handle high load demands with safety redundancy.

- Industrial Wiring & Cabling: Heavy-duty, fire-retardant cables for maximum safety and efficiency.

- Automation & Control Systems: PLC-based systems for monitoring and controlling production processes.

- Lighting: Energy-efficient LED lighting throughout production areas, storage, and administrative sections.

- Safety Systems: Emergency power backup (generators/UPS), grounding, and surge protection.

5. Utilities & Support Systems

A production facility is more than just machines and walls — it needs the right utilities to keep everything running.

Utilities Installed:

- Compressed Air Systems for machinery operation.

- Chilled Water & Cooling Systems to maintain product quality.

- Wastewater Treatment Units for eco-friendly operations.

- Fire Safety Installations including hydrants and extinguishing systems.

6. Commissioning & Final Handover

Once all installations were complete, our commissioning team rigorously tested every system:

- Machinery Trials to ensure production efficiency and quality.

- Safety Inspections for electrical, mechanical, and civil compliance.

- Training Sessions for Bake Parlor’s staff on operations and maintenance.

Finally, the facility was handed over ready for full-scale production — and Bake Parlor Industries could begin operations without delays.

7. Client Feedback & FK Engineering’s Commitment

Bake Parlor Industries appreciated FK Engineering’s commitment to quality, speed, and reliability. The project was completed within the planned timeline and budget, without compromising on industry standards.

At FK Engineering, we believe every project is a partnership. Our team ensures every client’s vision becomes a reality — just as we did for Bake Parlor.

Conclusion

From barren land to a fully operational industrial facility, FK Engineering delivered a true turnkey solution for Bake Parlor Industries. Civil, mechanical, electrical, utilities — every phase was executed with precision and passion.

If you are looking to establish or upgrade your industrial facility, FK Engineering is your trusted partner for complete solutions.