Introduction

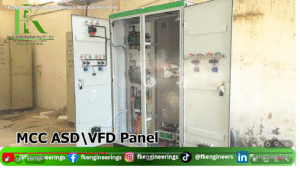

Motor Control Centers (MCCs) equipped with Adjustable Speed Drives (ASD) / Variable Frequency Drives (VFDs) play a vital role in modern industrial electrical systems. These panels provide precise motor speed control, improved energy efficiency, reduced mechanical stress, and enhanced process reliability across various industrial applications.

FK Engineering successfully completed the installation, wiring, and commissioning of an MCC ASD / VFD panel, ensuring full compliance with technical specifications, safety standards, and operational requirements. This project reflects FK Engineering’s expertise in electrical panel solutions and industrial power control systems.

Project Scope and Objective

The scope of this project included:

- Installation of MCC panel integrated with ASD / VFD units

- Power and control cable termination

- Verification of protection, interlocking, and control logic

- Pre-commissioning checks and functional testing

- Preparation of the system for safe operation and handover

The primary objective was to deliver a reliable, efficient, and user-friendly motor control solution that supports smooth process operation and long-term performance.

MCC ASD / VFD Panel Overview

An MCC ASD / VFD panel is designed to control multiple motors from a centralized location while allowing variable speed operation. Key features include:

- Energy-efficient motor speed control

- Soft starting and stopping of motors

- Reduced electrical and mechanical stress

- Improved process control and flexibility

- Integrated protection and monitoring systems

Such panels are widely used in pumps, fans, compressors, conveyors, and various industrial processes.

Installation and Execution Methodology

- The MCC panel was positioned as per approved layout drawings

- Proper leveling and alignment were ensured

- Panel anchoring was completed to provide mechanical stability

Adequate clearance was maintained for ventilation, maintenance access, and safe operation.

-

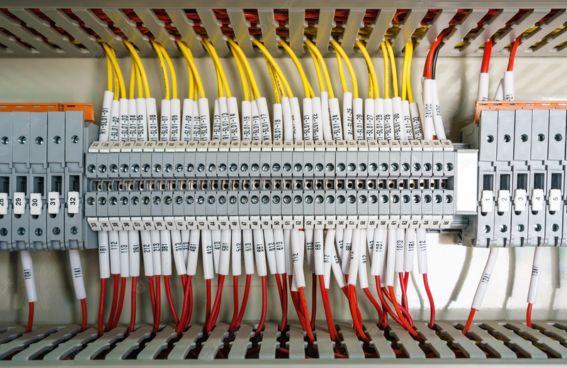

Power and Control Wiring

- Incoming and outgoing power cables were terminated using approved cable lugs

- Control wiring between VFDs, MCC feeders, and field devices was completed as per schematic diagrams

- Cable dressing and labeling were carried out for clear identification and ease of maintenance

All terminations were tightened to recommended torque values to prevent overheating and loose connections.

-

VFD Configuration and Parameter Setting

Each VFD was configured according to motor and process requirements, including:

- Motor rated voltage, current, and frequency

- Acceleration and deceleration ramps

- Speed limits and control modes

- Protection settings such as overload, under-voltage, and fault trips

Correct parameterization ensured optimal motor performance and system protection.

Testing and Pre-Commissioning Checks

Before energization, comprehensive testing was conducted, including:

- Continuity and insulation resistance testing

- Verification of phase sequence and earthing

- Functional testing of control circuits and interlocks

- Dry run testing of motors without load

All test results were verified and recorded to ensure system readiness.

Commissioning and Operational Verification

After successful pre-commissioning:

- The MCC ASD / VFD panel was energized under controlled conditions

- Motors were started at low speed and gradually ramped up

- Speed control, direction control, and protection functions were verified

- System performance was monitored for stable and fault-free operation

The panel performed as designed, meeting all operational and safety requirements.

Safety and Quality Assurance

Throughout the project, FK Engineering strictly followed:

- Electrical safety standards and best practices

- Lockout / tagout (LOTO) procedures during installation

- Proper PPE usage by all technical staff

- Quality control checks at each stage of execution

This ensured a safe working environment and high-quality project delivery.

Project Outcome

The successful installation of the MCC ASD / VFD panel resulted in:

- Improved energy efficiency and reduced power consumption

- Enhanced motor control and process flexibility

- Reduced mechanical wear on motors and equipment

- Reliable and safe electrical operation

The client received a fully tested and commissioned system ready for long-term industrial use.

Conclusion

The successful installation of the MCC ASD / VFD panel demonstrates FK Engineering’s strong capability in delivering customized motor control and industrial electrical solutions. Through careful planning, precise execution, and strict adherence to safety and quality standards, FK Engineering continues to support industrial clients with dependable and efficient electrical systems.

Tags / Keywords #FKEngineering#MCCPanel#VFDPanel#ASDPanel#MotorControlCenter#VariableFrequencyDrive

#IndustrialAutomation#ElectricalPanelManufacturing#IndustrialElectricalSolutions#PowerControlSystems#ElectricalEngineering#IndustrialProjects#PanelInstallation#EnergyEfficientSolutions#PakistanEngineering