When a rice mill runs smoothly, it’s easy to forget how many disciplines come together behind the scenes—geotechnical decisions that stop floors from cracking, cable routing that keeps motors humming, protections that trip when they should and never when they shouldn’t. At KK Rice Mills, FK Engineering delivered a tightly coordinated civil and electrical scope designed around uptime, safety, hygiene, and future expansion. This case study walks through what we built, how we phased it, and why the details matter for mill performance and lifetime cost.

Project Vision & Constraints

KK Rice Mills set a clear brief: consolidate operations into a robust, low-maintenance plant capable of sustained high throughput, consistent product quality, and predictable energy costs. The site presented three practical constraints:

- Variable soil bearing capacity across the plot, requiring foundation optimization rather than a one-size-fits-all design.

- Moisture and dust inherent to paddy handling and milling—two forces that damage concrete and electrical gear if not managed correctly.

- Tight construction windows to maintain supply commitments; phasing and parallel workstreams were mandatory.

FK Engineering’s approach combined civil robustness (so floors stay flat and drains stay clear) with electrical efficiency (so motors run cooler and bills run lower), and a commissioning process that proves every interlock before grain ever enters the line.

Civil Works: Built for Load, Moisture, and Movement

1) Site Grading, Drainage, and Access

We began with digital terrain modeling to optimize cut-and-fill and slope water away from structures. Peripheral drains and internal trench drains were sized for intense seasonal rain, while maintaining truck access gradients that keep loading efficient and safe. Concrete aprons were textured to reduce slip risk and to survive repeated forklift braking and turning.

2) Foundations & Superstructure

Rice mills are dynamic environments—hoppers, high-speed fans, destoners, graders, and conveyors all introduce vibration. We used a mixed foundation strategy:

- Isolated footings for columns supporting the main mill block.

- Thickened slab pads under heavy machines to distribute loads and limit differential settlement.

- Vibration control via elastomeric pads and grouted baseplates—protecting bearings, improving operator comfort, and extending machine life.

The superstructure blends RCC frames with structural steel mezzanines, giving stiffness where the process needs it and flexibility where equipment access and changeovers are likely.

3) Process Floors & Flatness Standards

For sifting, grading, and packaging, floor flatness drives everything from conveyor alignment to robotic palletizer accuracy. We specified floor flatness/levelness targets appropriate for mill operations and used laser screeding followed by power trowel finishing for cleanability. Hardened, dust-proofed surfaces resist abrasion and minimize airborne particulates.

4) Moisture Management & Hygiene

Moisture ruins concrete and attracts growth. We installed capillary breaks, polyethylene vapor barriers, and chemical DPC at wall-footing interfaces. Internal wet zones—like soaking/steeping or wash-down areas—received epoxy or PU coatings and coved skirtings to eliminate dirt traps. Floor slopes were set to micro-gradients so wash water evacuates without pooling.

5) Material Handling Architecture

We planned vertical lift corridors for bucket elevators and defined maintenance landings at strategic elevations to keep technicians safe and productive. Service aisles are wide enough for pallet jacks and allow lockout-tagout (LOTO) stations to be mounted at eye level.

6) Storage, Silos & Receiving

The paddy receiving pit, pre-cleaner bay, and raw material silos sit on stiffened slabs with impact zones where drop heights and impact forces are greatest. We integrated dust extraction duct sleeves and access hatches so future retrofits don’t require demolition.

7) Fire Safety & Egress

A clear fire compartmentation strategy separates high-risk areas. We added pressurized stairwells, illuminated egress signage, and hydrant risers aligned with the electrical rooms’ protection scheme. The civil and electrical fire strategies were designed together so detection/alarms match the physical paths people actually use.

Electrical Works: Power that’s Clean, Controllable, and Safe

1) Incoming Power & Substation Design

At the heart is a compact substation comprising transformer, HT panel, and LT distribution with a clean segregation of protection zones. We performed short-circuit and coordination studies to ensure upstream devices trip first and protect downstream assets. Transformers were selected for low losses and future headroom, and all terminations follow IEC/NEC best practices for creepage and clearance.

2) Main Distribution Boards (MDBs), MCCs & Drives

The plant’s load profile is motor-heavy—elevators, blowers, polishers, conveyors—so our MCC architecture used modular withdrawable feeders for easy maintenance. Variable Frequency Drives (VFDs) were applied where airflow or conveyor speed benefits from modulation, cutting energy use and reducing mechanical stress. Power Factor Correction (PFC) brings the system near unity to avoid utility penalties and keep conductors cooler.

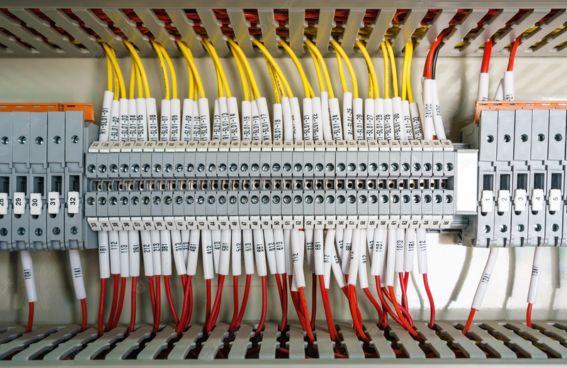

3) Cable Management & Earthing

We deployed galvanized cable trays with segregated routes for power, control, and instrumentation, reducing noise and simplifying troubleshooting. The earthing grid was modeled to achieve low earth resistance; every major panel, motor frame, and structural steel segment is bonded. This ensures touch safety, improves surge performance, and stabilizes VFD reference planes.

4) Lighting & Small Power

Good lighting is quality control. We specified high-efficacy LED luminaires with glare control in inspection areas and increased vertical illuminance where operators read bags and labels. Emergency lighting and photoluminescent path marking support safe evacuation during outages. Small power outlets and maintenance receptacles are positioned to eliminate unsafe extension-cord runs.

5) Controls, Instrumentation & Automation Readiness

Even where the mill retains manual operations, we wired for tomorrow:

- PLC-ready I/O marshaling with labeled terminations, spare cores, and documented drawings.

- Shielded control cables with proper drain wiring and segregation from power to prevent nuisance trips.

- Sensor points for motor temperature, bearing vibration, pressure differentials at filters, and dust collector performance—so the plant can adopt predictive maintenance without rewiring.

6) Protection, Monitoring & Quality of Power

We installed multifunction meters at main and sub feeders to track energy consumption by process area. Harmonic filters were allocated where nonlinear loads concentrate, protecting sensitive electronics and improving transformer life. Overload, earth-fault, and thermal protections are coordinated so a single fault doesn’t black out an entire line.

7) Backup Power & Solar-Ready Interface

A diesel genset with an automatic transfer switch (ATS) ensures critical loads—control systems, elevators to clear in-process material, safety lighting—stay alive during outages. The main switchboard has a solar-ready bus coupling point and space for bidirectional protection, so KK Rice Mills can integrate PV without major rework.

Construction Management: Safe, Fast, Documented

Phased Execution

We used a zoned schedule: civil foundations and slabs first in the receiving and pre-cleaner areas, while structural steel prefabrication proceeded offsite. As soon as bays cured, electrical teams followed with tray installation and early pulling to compress the critical path—without cross-trades clashes, thanks to coordinated 3D markups.

Quality Assurance

- Concrete control: mix design verification, slump checks, core sampling, and laser level surveys for flatness.

- Electrical tests: insulation resistance, primary injection for protection devices where applicable, earth resistance, and loop impedance in final circuits.

- Functional testing: dry runs for conveyors; directional checks on all rotating equipment; interlock testing for dust extraction so the system can’t run unprotected.

HSE Culture

Hot works permits, energized work controls, and temporary edge protections at mezzanines kept the site safe. Daily toolbox talks focused on confined-space awareness around pits and ducts, and lockout logs were audited before every shift change.

Commissioning: Proving Performance Before Grain Enters

Our commissioning methodology mirrors the way KK Rice Mills actually operates:

- Cold Commissioning: Power-on checks, PLC I/O simulation (where installed), VFD parameterization, and motor bump tests.

- Dry Commissioning: Run conveyors, fans, and elevators without product to validate rotation, vibration, and current draw; fine-tune VFD ramps to reduce spillage on start/stop.

- Wet/Live Commissioning: Introduce controlled batches to verify throughput, dust extraction balance, and trip thresholds. Operators were trained to read the new dashboards and interpret alarms—not just silence them.

We delivered as-built drawings, single-line diagrams, cable schedules, and an O&M manual that reads like a field guide: clear photos, torque specs, breaker settings, and step-by-step LOTO procedures.

Results: Reliability You Can Feel (and Measure)

- Higher Uptime: Robust floors and vibration-managed foundations keep alignments true, while coordinated protection avoids nuisance trips.

- Lower Energy per Ton: VFDs, PFC, and harmonic mitigation combine for measurable savings and cooler-running equipment.

- Cleaner Operations: Hygienic civil details and balanced dust extraction reduce rework and housekeeping labor.

- Future-Proofing: Spare capacities, solar-ready switchgear, and instrumented assets make upgrades straightforward without shutdown-heavy rewiring.

Lessons Learned & Recommendations

- Design for Maintenance: Every access platform, every MCC drawer, every labeled core saves hours later. Build it into day one.

- Civil–Electrical Symmetry: Drainage and dust control are as much electrical reliability strategies as they are architectural ones.

- Data from the Start: Even if automation is phased, run metering and sensor wiring now. Visibility pays for itself quickly.

- Commission Like You Operate: Simulate loads, test interlocks, and involve operators early so handover is a non-event.

Conclusion

At KK Rice Mills, FK Engineering delivered a plant infrastructure where civil resilience and electrical intelligence reinforce each other. The result is a mill that stands up to daily grind—literally—and gives its team the tools to run safely, efficiently, and confidently. As market demands evolve, the mill’s foundations (physical and electrical) are ready for expansions, automation layers, and renewable integration. That’s the difference between “built” and engineered—and it’s the standard FK Engineering brings to every project.