When it comes to food processing industries, a flour mill stands at the heart of Pakistan’s agricultural economy. The demand for reliable, hygienic, and efficient production facilities has never been greater. At Sindh Flour Mill, FK Engineering delivered a turnkey solution—covering civil, mechanical, and electrical works—transforming a bare plot into a fully functional flour milling plant. From foundation design to power distribution, from machinery installation to safety systems, every stage was engineered with precision and foresight.

This article highlights the comprehensive setup FK Engineering executed at Sindh Flour Mill, reflecting our commitment to industrial excellence.

Project Scope

The client’s vision was clear: establish a modern flour milling facility capable of consistent production, safe working conditions, and long-term scalability. FK Engineering was entrusted with complete responsibility:

- Civil Works – Structures, foundations, silos, storage, drainage, and hygienic flooring.

- Mechanical Works – Machinery installation, alignment, conveyors, elevators, and packaging.

- Electrical Works – Power distribution, MCCs, VFDs, lighting, automation readiness, and earthing.

- Safety & Utilities – Fire protection, ventilation, dust extraction, and backup power.

The result is a state-of-the-art flour mill ready to handle continuous production with minimal downtime.

Civil Works: Building a Strong Backbone

1) Site Preparation & Foundations

The Sindh Flour Mill site demanded robust soil stabilization. FK Engineering began with grading, compaction, and designing reinforced concrete foundations to withstand heavy vibrations from roller mills and elevators. Special load-bearing pads were cast for major equipment to prevent settlement or misalignment.

2) Mill Structure & Storage Units

- RCC frame structures provide rigidity and durability.

- Steel mezzanines and service platforms were installed for equipment access.

- Silo foundations were designed for vertical loads and wind forces, ensuring safe bulk grain storage.

3) Hygienic Flooring & Drainage

Flour mills face dust and moisture issues. We applied epoxy-coated concrete flooring with smooth finishes for easy cleaning and hygiene compliance. Internal drainage slopes direct water away from production zones, preventing contamination.

4) Ventilation & Dust Management

Civil ducts and openings were integrated to house dust extraction lines and fresh-air ventilation, reducing explosion risks and ensuring operator comfort.

Mechanical Works: Installing the Heart of Milling

1) Core Milling Machinery

FK Engineering handled the installation and alignment of:

- Roller mills for grinding.

- Plansifters for particle separation.

- Purifiers and cleaners for wheat preparation.

- Automatic packaging machines for bagging flour.

Alignment was carried out with laser tools to ensure smooth operation, reducing wear and tear.

2) Conveying & Material Handling

- Bucket elevators were erected with safety casings.

- Belt conveyors and chain conveyors were installed for grain and flour movement.

- Hoppers and bins were fitted with vibration-damping systems.

3) Ancillary Systems

- Dust collectors and cyclones keep the facility clean and explosion-safe.

- Airlocks and rotary valves prevent material loss and maintain system pressure balance.

Electrical Works: Powering the Mill

1) Substation & Power Distribution

FK Engineering established a dedicated transformer and HT/LT panels for the flour mill. Proper protection coordination was implemented through circuit breakers, relays, and surge protection devices.

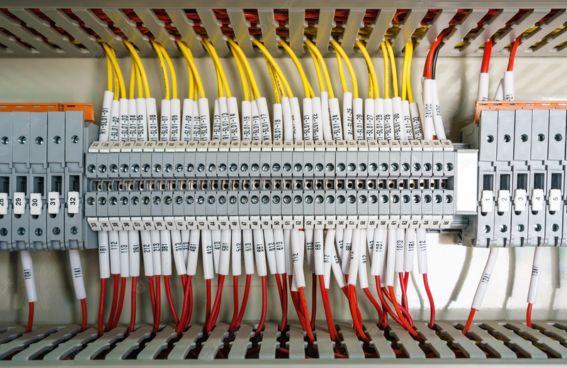

2) Motor Control Centers (MCCs) & Drives

- MCCs were designed for withdrawable feeders for easy maintenance.

- VFDs (Variable Frequency Drives) were deployed for conveyors and fans, reducing power consumption.

- Automatic Power Factor Correction (APFC) systems were installed to keep the mill’s power factor close to unity.

3) Cable Management & Earthing

- Cable trays and ducts were installed with segregation for power and control.

- A comprehensive earthing network ensures operator safety and equipment reliability.

- Lightning protection was included for plant-wide safety.

4) Lighting & Small Power

Energy-efficient LED lighting with dust-proof fixtures was installed across all floors. Emergency lights and exit signage were integrated into escape routes for compliance with industrial safety codes.

Safety & Utility Systems

Fire Protection

- Fire hydrant system with dedicated pumps and water storage.

- Smoke detectors and alarms in control rooms.

- Emergency exit routes designed in coordination with civil works.

Backup Power

A diesel genset with automatic transfer switch (ATS) ensures uninterrupted operation of critical loads like conveyors, control systems, and lighting during outages.

Dust & Hygiene

Dust extraction systems and hygienic coatings reduce contamination and keep air quality within safe limits, ensuring compliance with food safety standards.

Commissioning & Training

FK Engineering doesn’t stop at construction—we ensure the mill is ready to operate from day one.

- Cold testing of electrical panels, motor rotation checks, and protection relay calibration.

- Dry runs of conveyors, elevators, and milling machines without product.

- Live commissioning with controlled wheat batches to test throughput and refine equipment settings.

- Operator training on electrical safety, equipment operation, and preventive maintenance.

Results Achieved

The completed Sindh Flour Mill setup has delivered:

- Stable production with reduced downtime.

- Improved energy efficiency through VFDs and optimized MCC design.

- Safe and hygienic environment for flour processing.

- Future scalability, with space and infrastructure ready for automation and renewable integration.

Conclusion

The Sindh Flour Mill project showcases FK Engineering’s ability to handle end-to-end industrial solutions. By delivering civil, mechanical, and electrical works under one roof, we ensured seamless coordination, faster project completion, and reduced costs for the client.

With this setup, Sindh Flour Mill now stands as a model of modern flour milling in Pakistan—robust, efficient, safe, and ready for growth.