At Mehran Commercial, the reliable supply of electricity is the backbone of business continuity. From shops and offices to storage areas and service facilities, every activity depends on uninterrupted and stable power. Recognizing this, FK Engineering carried out a comprehensive transformer maintenance program and executed essential High Tension (HT) works at the site. The project not only restored efficiency but also laid down a framework for long-term electrical reliability.

Why Transformer Maintenance Matters

Transformers are critical assets in any commercial hub. They step down high-voltage electricity from the utility grid into safe, usable levels for distribution. But like any machine, they are subject to wear, heating, oil degradation, and insulation aging. Without proper care, the risks include:

- Overheating and energy losses

- Voltage fluctuations that damage sensitive equipment

- Unexpected breakdowns leading to blackouts

- Fire hazards caused by insulation failure

FK Engineering approached Mehran Commercial’s transformer with a philosophy of preventive maintenance—identifying small issues before they become costly outages.

Scope of Transformer Maintenance at Mehran Commercial

The maintenance program covered both mechanical integrity and electrical performance, ensuring the transformer could operate safely for years to come.

1) Visual and Structural Inspection

- Checked transformer tank for oil leaks, rust, or cracks.

- Inspected bushings and terminals for cracks or carbonization.

- Verified conservator, breather, and silica gel condition to confirm moisture protection.

2) Oil Testing and Treatment

Transformer oil is its lifeblood. FK Engineering carried out:

- Dielectric strength test to ensure proper insulation.

- Moisture content analysis to avoid breakdown under load.

- Filtration and topping up of oil to restore dielectric properties.

3) Electrical Testing

- Insulation Resistance (IR) testing of windings.

- Turns Ratio (TTR) test to confirm winding integrity.

- Load loss and no-load loss monitoring to measure efficiency.

- Partial discharge inspection for early signs of insulation deterioration.

4) Cooling and Protection Systems

- Verified cooling fans and radiators for smooth operation.

- Calibrated Buchholz relay, temperature sensors, and pressure relief devices.

- Checked protection circuits and alarms for accuracy.

The transformer was restored to near-factory performance, ensuring stable supply to Mehran Commercial.

High Tension (HT) Works

Alongside transformer maintenance, FK Engineering executed critical HT works to modernize and safeguard the high-voltage system.

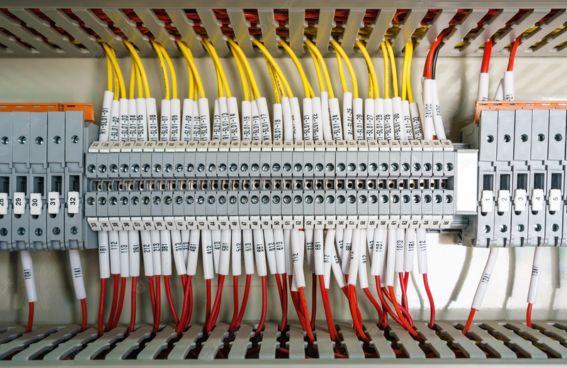

1) HT Panel Overhaul

- Inspected HT switchgear for mechanical wear and dust accumulation.

- Carried out contact resistance testing of breakers.

- Cleaned and lubricated moving parts for smooth switching.

- Verified protection relays, ensuring quick fault clearance.

2) Cable and Termination Work

- Inspected 11kV HT cables for thermal damage and sheath deterioration.

- Replaced and re-terminated old joints with heat-shrink terminations.

- Conducted High-Pot (Hi-Pot) testing to confirm insulation reliability.

3) Earthing System Upgrade

- Measured earth resistance and reduced it to safe levels.

- Strengthened earth grid and bonding to prevent dangerous touch voltages.

- Ensured transformer, HT panel, and building steel structures were fully interconnected.

4) Protection Coordination

- Adjusted relay and breaker settings to coordinate with utility supply.

- Ensured fault isolation occurs at the nearest point, preventing large-scale outages.

- Integrated monitoring for future predictive maintenance.

Safety & Compliance

FK Engineering’s work at Mehran Commercial followed IEC and NEPRA electrical safety standards, including:

- Lockout/Tagout procedures (LOTO) during maintenance.

- Arc-flash protection for workers.

- Proper barricading and warning signage during HT handling.

- Documentation for regulatory and insurance compliance.

Benefits Delivered

The project delivered measurable improvements:

- Reduced Downtime: The transformer now runs cooler and more reliably.

- Lower Energy Losses: Improved oil and winding conditions reduce wastage.

- Enhanced Safety: Modernized HT gear and earthing protect both people and equipment.

- Future Readiness: Clear documentation and test reports form a baseline for predictive maintenance.

Conclusion

By completing transformer maintenance and HT works at Mehran Commercial, FK Engineering reinforced its reputation for delivering safe, efficient, and future-ready electrical solutions. The project ensures businesses at Mehran Commercial enjoy stable power, reduced operational risks, and peace of mind knowing their electrical backbone is engineered for long-term reliability.