HT Maintenance & VCB: FK Engineering’s Critical Shutdown at Palpex Pharmaceuticals

Introduction

Palpex Pharmaceuticals (Pvt.) Ltd, a leading company in the pharmaceutical sector, recently entrusted FK Engineering with the responsibility of performing high tension (HT) maintenance and servicing of vacuum circuit breaker (VCB) units during a scheduled shutdown. This maintenance was essential to ensure the electrical reliability, safety, and continuous production capacity of the facility. The HT system and VCBs are the backbone of the power supply infrastructure, and any failure can lead to severe disruptions, quality risks, or financial losses.

This article details how the project was planned, executed, and what outcomes were achieved, along with technical insights and best practices. This can serve as a template for similar industrial maintenance operations.

Project Background

• Location: Palpex Pharmaceuticals, Karachi

• Scope: Full inspection, servicing, testing, and restoration of HT switchgear and Vacuum Circuit Breaker units

• Duration: Scheduled maintenance over a 1-day shutdown window

• Objective: Improve electrical safety; reduce risk of failures; extend lifespan of equipment; ensure regulatory compliance

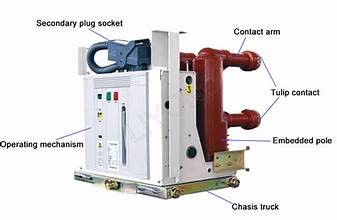

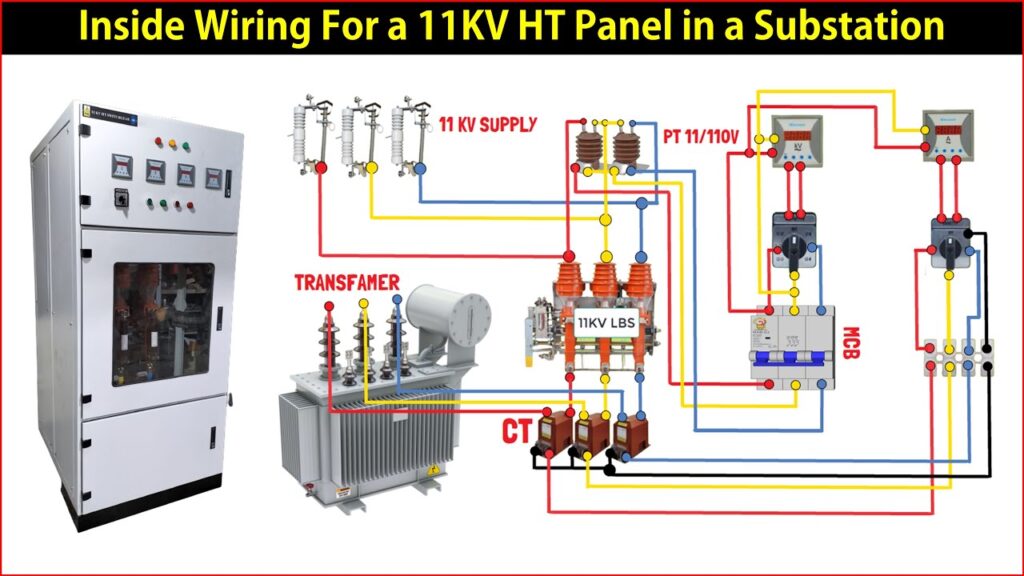

HT systems in pharmaceutical plants often supply critical processes. The VCB units within the HT switchgear are crucial because they interrupt load current and protect the system during fault events. If the VCB fails or its performance degrades, it can lead to unsafe operating conditions or unplanned downtime.

Preparation & Planning

- Pre-shutdown Survey

FK Engineering conducted a preliminary assessment of Palpex’ s HT switchgear and VCB units. This included visual inspection, reviewing past maintenance logs, identifying known weak points, and quantifying operating cycles of the breakers. - Safety & Permits

Comprehensive safety planning was done: lockout/tagout (LOTO) procedures were established; electrical isolation; work permits were secured; roles and responsibilities were defined. Workers were briefed about personal protective equipment (PPE), potential electrical risks, and emergency procedures. - Procurement of Spares & Tools

All necessary spare parts (contacts, springs, coils, insulating components) and calibrated testing equipment (megohmmeter, contact resistance meter, thermal camera) were ready beforehand. This minimized delays during shutdown. - Scheduling & Coordination

The maintenance was coordinated with the production department to determine the minimal acceptable downtime. All teams—electrical, safety, operations—were aligned. Shift timings, manpower, and resource availability were scheduled.

Technical Procedure

Below is a summary of the key technical steps taken for HT maintenance & VCB servicing. The procedure follows best practices mentioned in industrial guidelines and articles.

- Isolation & De-energizing

• The HT supply was completely deactivated.

• Proper earthing of panels and components done to ensure no residual or back-feed.

• The VCB units were racked out of their compartments (if draw-out type) and placed in safe positions for servicing. - Visual & Mechanical Inspection

• Inspect all external parts of switchgear: enclosure, doors, hinges; check for corrosion, deformation, rust.

• Check movement of operating mechanisms, springs, levers: ensure lubrication points are free and moving freely.

• Check alignment and condition of mechanical linkages. - Internal Inspection & Cleaning

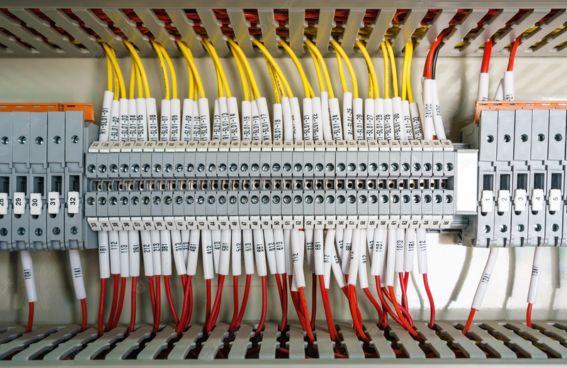

• Remove dust, dirt, and foreign objects from inside the VCB compartment and switchgear busbars. Cleaning done with dry, lint-free cloths; mild solvents if needed (but ensuring no moisture remains).

• Inspect insulation surfaces, including support insulators for cracks, color changes, degradation. - Contact Wear & Vacuum Interrupter Check

• Measure erosion / wear of main contacts: Compare to manufacturer’s specs. Replace if beyond allowable limit.

• For vacuum interrupters: test vacuum integrity (leakage, ability to maintain vacuum, internal arcing under test voltage) as per industry standards - Electrical Testing

• Insulation resistance tests across phases, phase to earth, and meter/control circuits using megohmmeters.

• Contact resistance measurement to identify high resistance joints or deteriorated contacts.

• Operate the breaker in open/close operations multiple times to check smooth functioning. - Lubrication & Adjustment

• Lubricate hinges, moving parts, springs, and mechanical linkages with recommended lubricants. Avoid over-lubrication.

• Adjust stroke, contact gap, closing & tripping times, springs tension as per technical specifications. - Re-assembly & Final Checks

• Re-rack the VCB units (or re-install) into their compartments. Secure all bolts, panels.

• Conduct functional tests: verify that auxiliary contacts, indicators, interlocks operate correctly.

• Remove temporary earths and grounding.

• Confirm readiness to re-energize.

Challenges & Solutions

Challenge How FK Engineering Addressed It

Limited shutdown duration Careful planning, parallel team work, pre-assembling spares, prioritizing critical tasks.

Ensuring strict safety compliance Use of proper PPE; work permit & LOTO; safety briefings; test isolation; supervision.

Accuracy in diagnosis (hidden faults) Use of diagnostic tools (thermal imaging, contact resistance, vacuum testing) rather than only visual checks.

Environmental factors (dust, humidity) Deep cleaning; moisture control; ensuring enclosures sealed; drying if moisture present.

Outcomes & Benefits

After the maintenance, the following positive results were recorded at Palpex:

• Improved Reliability: VCB units now meet spec for contact resistance, vacuum integrity, mechanical performance. Reduced risk of electrical faults.

• Enhanced Safety: All insulation resistance measurements within safe limits; mechanical parts and linkages functioning properly; interlocks & safety devices verified.

• Extended Lifespan: By replacing worn components and applying proper adjustments, life expectancy of HT switchgear & VCBs increased significantly.

• Reduced Downtime Risk: The plant avoided unplanned downtime; the scheduled shutdown was sufficient to cover all critical tasks.

• Cost Savings: By catching issues early (before failure), FK Engineering helped Palpex avoid more expensive repairs or replacements in future.

Best Practices & Guidelines (Industry Standards)

FK Engineering followed guidelines that align with widely-accepted best practices in HT and VCB maintenance. Some of these include:

• Regular preventative maintenance cycles; monitoring number of operations of breakers; replacing contacts / interrupters beyond thresholds.

• Visual inspection at least annually; more frequent in harsh environments.

• Having detailed maintenance procedure and checklist; documentation of test results (contact resistance, insulation, etc.).

• Using proper safety practices: de-energization, earthing, LOTO, PPE.

Recommendations for Palpex & Future Work

• Maintain a detailed logfile/checklist for HT & VCB maintenance, including dates, test data, and parts replaced.

• Implement condition-based monitoring tools (infrared thermography, ultrasonic detection) for early detection of problems.

• Plan regular maintenance intervals based on actual breaker operations and environmental severity rather than just time.

• Train internal Palpex staff in basic inspections, safety, and early warning indicators.

Conclusion

The HT Maintenance & VCB project by FK Engineering at Palpex Pharmaceuticals showcases how careful technical planning, rigorous safety standards, and precise execution can significantly enhance electrical system reliability. Maintenance of high-tension switchgear and vacuum circuit breaker units is not optional — it is essential for safe operations, uninterrupted production, and cost-effectiveness. With the right protocols, testing, and commitment, FK Engineering in your case ensures that critical electrical infrastructure remains robust and trustworthy.

Tags & Keywords

#HTMaintenance #VacuumCircuitBreaker #SwitchgearMaintenance #PreventiveMaintenance #ElectricalSafety

#IndustrialShutdown #PalpexPharmaceuticals #ConditionMonitoring #ElectricalEngineering